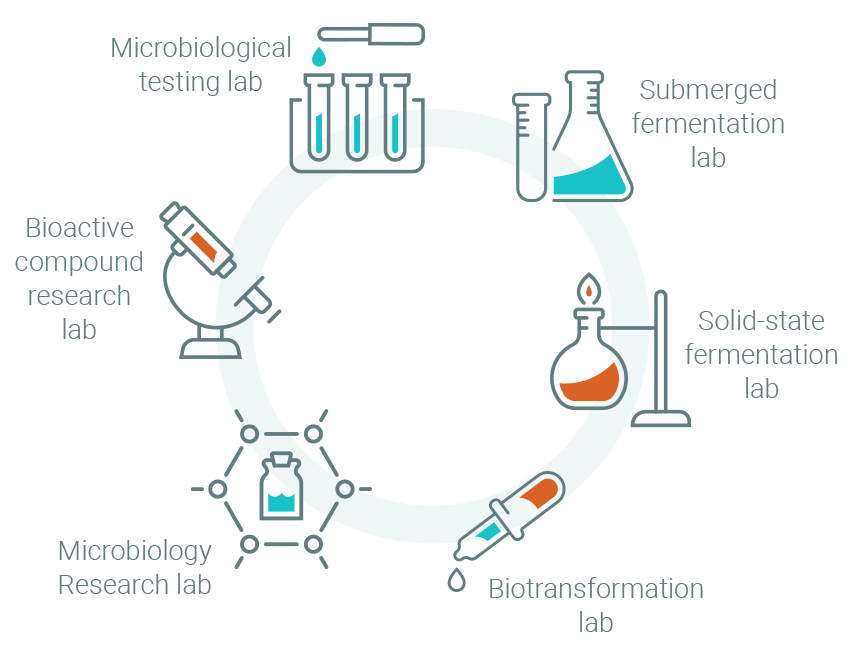

State-of-the-art fermentation technology

All our ingredients are manufactured in well-established facilities provided with industrial-scale bioreactors, membrane filtration equipment, separators, freeze-drying machine and automatic control systems.

Bioreactors used for fermentation are automatically controlled by state-of-the-art computers. Modern clean-in-place (CIP) systems, equipped with automation software, allow a simple analysis of every aspect of the process.

The highest quality ingredients are manufactured according to our advanced fermentation technology in established facilities with strict quality assurance systems (in accordance with GMP foods, HACCP and ISO22000), which always meet consumer requirements for safety, effectiveness and economic benefits.

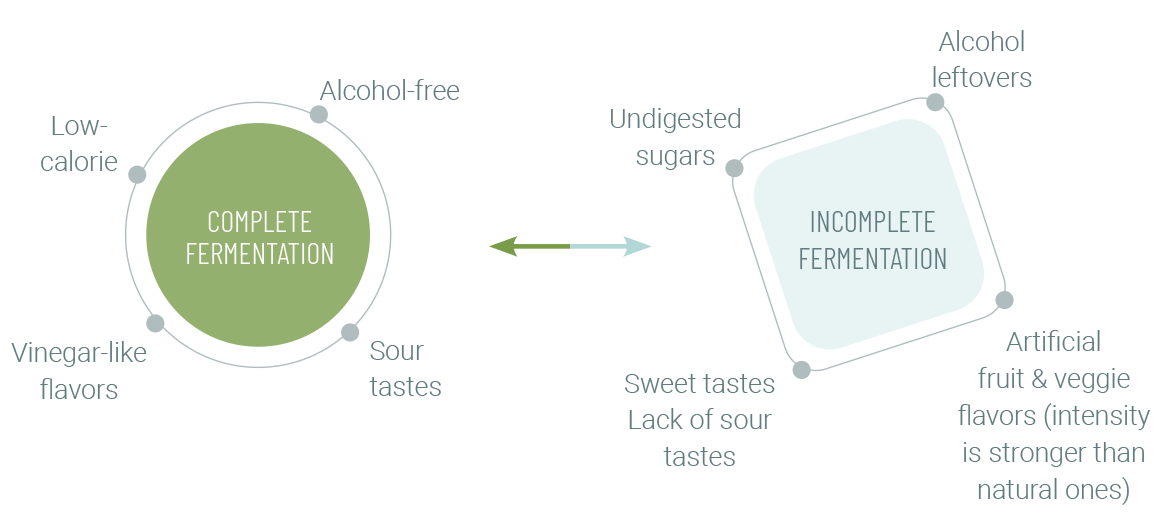

Fermedics applies

a fully-controlled and complete fermentation, a must to be effective.

What are the differences between fully-controlled, semi-controlled and natural fermentation?

| Fully-controlled by Fermedics |

Semi-controlled | Natural | |

| Oxygen controlling | |||

| Temperature controlling | |||

| Homogeneity | High | Low | Low |

| Bioactivation | High | Low | Low |

| Risk of contamination | Low | High | High |